Generating nuclear power requires withstanding extreme conditions—intense heat, pressure, and radiation—that challenge every component of a reactor each time it operates. Naturally, engineering the perfect apparatus is a difficult task, but researchers continue to discover astonishing ways to advance nuclear technology. The latest breakthrough involves a tiny chip with not-so-tiny performance.

### New Microelectronic Sensors for Nuclear Reactors

In a recent announcement, University of Maine researchers unveiled new microelectronic sensors capable of tolerating the high radiation levels and extreme temperatures found inside a nuclear reactor’s core. At the same time, these sensors capture real-time operational data, providing engineers and operators with invaluable insights into the reactor’s activity.

“Since many advanced reactors currently under development operate at these temperatures, there is a high demand on the sensors to monitor them,” said Mauricio Pereira da Cunha, the project’s principal investigator.

### Firing Up the Heat

The sensor is designed to function within the furnace of nuclear fission reactors, which generate vast amounts of energy by splitting heavy atomic nuclei. Specifically, the researchers aim to install these sensors in advanced high-temperature reactors that use helium gas and ceramic materials to generate nuclear energy more efficiently and safely.

These reactors operate at higher temperatures than traditional ones, achieving greater thermal efficiencies, but existing sensors often cannot withstand such conditions. Addressing this challenge, the research team drew on two decades of expertise refining similar sensors.

### Tiny Sensor, Big Impact

Over the past two years, the team developed and rigorously tested a sensor robust enough to endure the extreme environment inside next-generation reactors. Alongside durability, they focused on miniaturizing the sensor to broaden its potential applications.

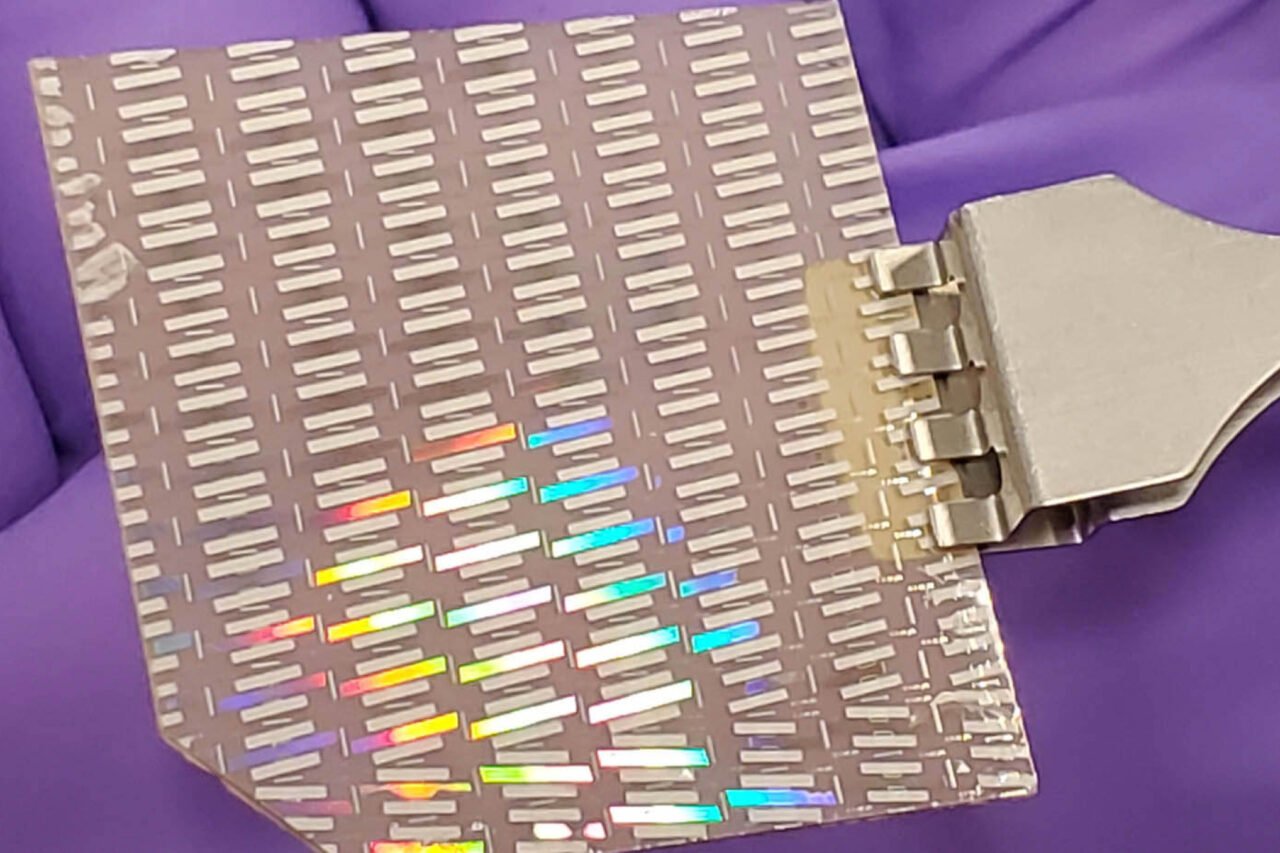

For the project, seven sensors were created and tested at the Nuclear Reactor Laboratory at Ohio State University, according to a report by the Department of Energy’s Office of Nuclear Energy. Each sensor measured just 100 nanometers thick—around 1,000 times thinner than a human hair—and featured platinum-based alloy electrodes protected by alumina caps.

Remarkably, all seven sensors remained fully functional and showed no signs of degradation after five days of exposure to the reactor operating at maximum power and temperatures nearing 1,500 degrees Fahrenheit (800 degrees Celsius). Early analyses also suggest impressive resilience against radiation.

“In addition to extreme temperatures, we’re now also exposing these sensors to intense, in-core levels of nuclear radiation at the same time,” noted Luke Doucette, the project’s senior research scientist. “This adds an entirely new dimension of difficulty in terms of what types of sensor materials can survive in these conditions and remain functional.”

### A Promising Step Forward

These advancements mark a promising step toward enhancing the safety and efficiency of nuclear reactors by providing continuous, accurate monitoring under conditions once thought too extreme for reliable sensing. As advanced reactors continue to evolve, innovations like these sensors will play a crucial role in shaping the future of nuclear energy.

https://gizmodo.com/sensor-survives-reactor-level-heat-and-radiation-paving-the-way-for-real-time-monitoring-2000678729